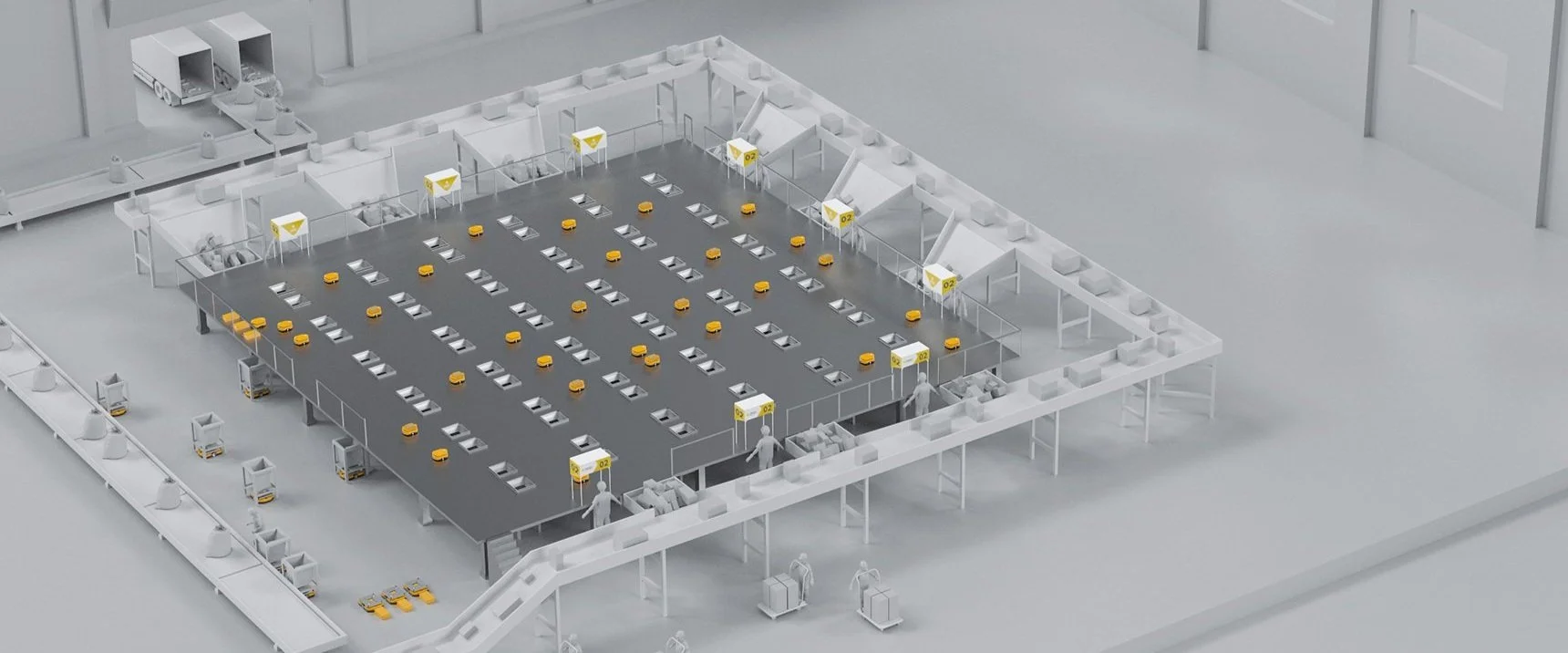

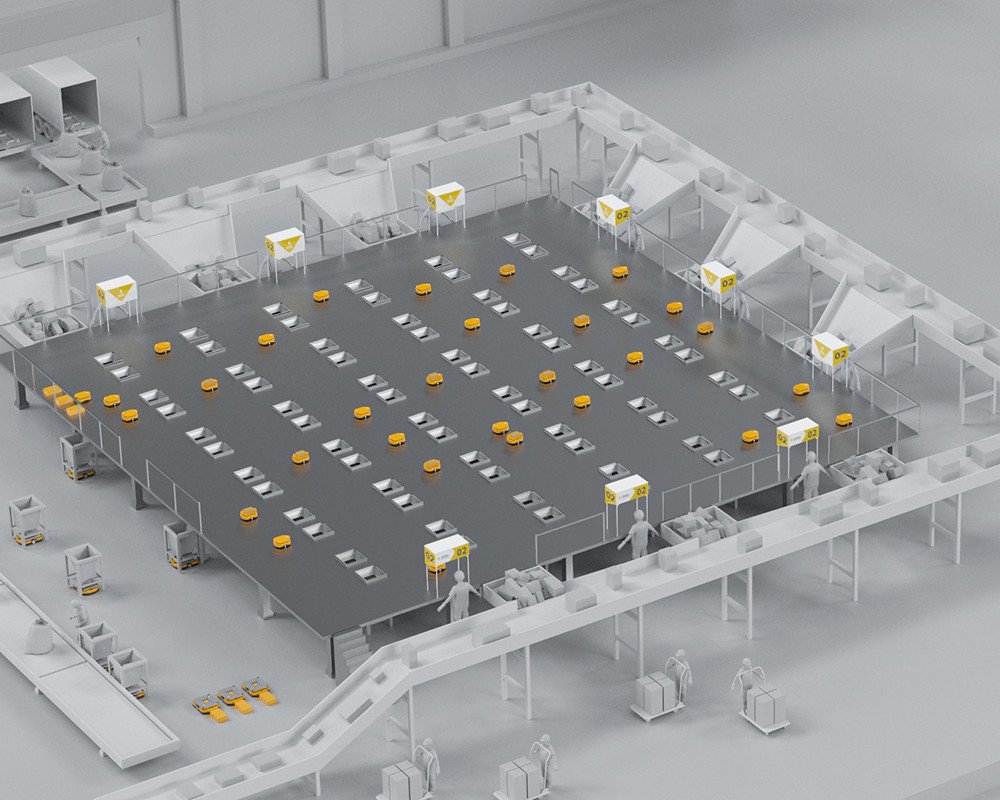

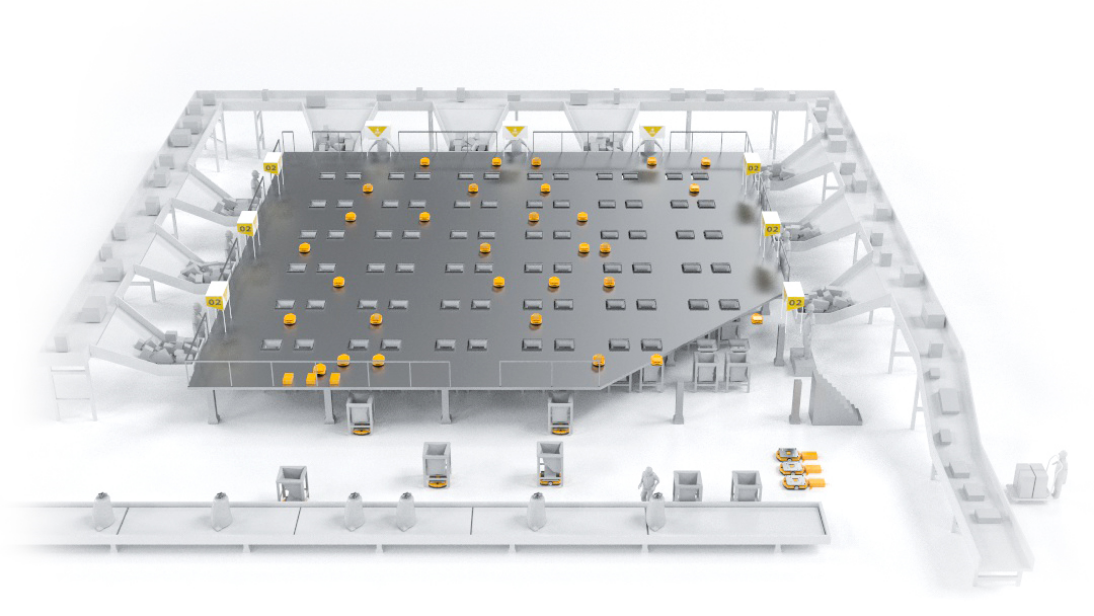

The main benefits brought by MegaBOT’s Platform Sorting Solution is its ability to satisfy high sorting demands with relatively few robots and sorting grids due to its unique configuration. The intelligent sorting feature is brought to its forefront here, highlighting its ability to perform automated sorting with precision & efficiency. The main make-up of the Platform Sorting Solutions are; Steel Platform (fixed system), Robot Sorting System (core system), Collecting Pack System and Conveying System.

Intelligent sorting, precise, efficient, and highly cost-effective

Application Scenarios:

Similar to Table Sorting Solution, except the platform can be single-layered, multi-layered, single-fingered or multi-fingered. Ideal for large sorting or picking centers in parcel and express sorting, commodity sorting and other related scenarios.

High productivity and efficiency

· 350 robots operating continuously for 24 hours, processing 400,000 parcels.

· AI algorithm maximizes the sorting efficiency, which is 2- 3 times higher than that of manual sorting.

· Support to increase the operation of robots during peak seasons to quickly improve efficiency in a short time.

High Stability and Accuracy ≥99.99%

· A single robot failure will not affect the overall system operations, with high stability and fault tolerance capabilities.

· If the input information is correct, the sorting accuracy of the system can reach up to 99.99%, with a margin of error that is close to zero.

Flexible Dispatch for Optimal Operations

· The system dispatches hundreds of robots for collaborative operations at the same time, reasonably allocates tasks, and plans optimal paths.

· For visual management, the system monitors robot dynamics in real time, so that you situation of any robot can be viewed at any time.

Quick Deployment with Convenient Operations and Maintenance

· The system has a short construction period, and it usually only takes 1- 2 months from signing the contract to starting operations.

· The implementation of solutions is low difficulty, can be adapted to various sites, and has a short cycle and low cost.

· The system is simple to operate, has low training costs, high system stability, and low maintenance costs.

Low Floor Space Occupation, Saving Space

· Occupied space is greatly reduced, taking up half as much space than other sorting methods, which effectively reduces space costs.

· Normally speaking, a site of about 1,300m² can be divided into 240 grids, allowing a high space utilization rate.

Auto Sorting to Save Labor

· Intelligently identifies the parcel's barcode, and judges the corresponding grid to discharge it independently.

· Achieves automation of feeding, code reading, weighing, sorting, and parcel collecting, thus reducing manpower requirements by 50%- 60%, and reducing labor intensity.